Daidaita Injin Aunawa (CMMs) - Gidajen Ma'auni na 3D

Hakanan aka sani da 3 - Injinan Auna Girma (CMMs), CMMs ɗin mu sune ginshiƙan tsarin binciken mu. Kamar yadda aka nuna a hoton da ke ƙasa, su na'urori ne masu inganci waɗanda ke da ikon auna girman sashe tare da madaidaicin matakin micron.

CMMs suna samun aikace-aikace masu yawa a cikin masana'antu daban-daban, daga sararin samaniya zuwa likitanci. A cikin sararin samaniya, ana amfani da su don bincika abubuwan da ke da mahimmanci kamar injin turbine, tabbatar da cewa ko da mafi ƙarancin girman suna cikin ƙayyadaddun haƙuri. A fannin likitanci, suna tabbatar da daidaiton kayan aikin tiyata da kayan aikin dasa

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Aunawa Range | [X] mm (tsawon) x [Y] mm (Nisa) x [Z] mm (tsawo), daidaitawa zuwa nau'ikan sassa daban-daban |

| Daidaito | Har zuwa ± 0.001 mm, yana ba da ingantattun ma'auni |

| Nau'in Bincike | An sanye shi da taɓawa - yana haifar da bincike don ma'auni na gabaɗaya da binciken bincike don ƙayyadaddun bayanan martaba |

| Daidaituwar Software | Yana haɗawa da masana'antu-manyan software na metrology don nazarin bayanai da bayar da rahoto |

Daidaita Injin Aunawa (CMMs) - Gidajen Ma'auni na 3D

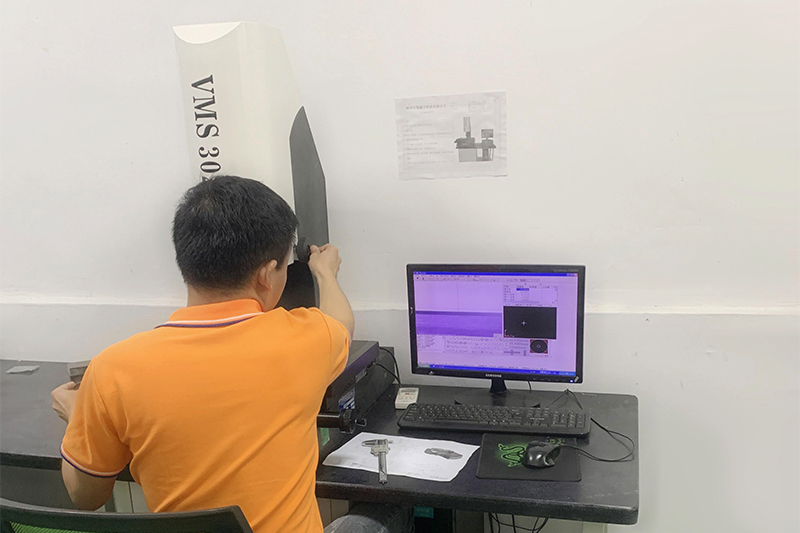

Kwatancen gani suna da makawa don bincikar sassan da ba na sadarwa ba. Hoton yana nuna ƙa'idar aiki na na'urar kwatancen gani, inda aka ɗaukaka ɓangaren kuma an tsara shi akan allo don aunawa.

Waɗannan suna da amfani musamman a cikin masana'antar lantarki, inda ake buƙatar bincika ƙanana da ƙaƙƙarfan kayan aikin. Alal misali, ana iya amfani da su don auna ma'auni na masu haɗin haɗin micro ko daidaita alamun allon kewayawa. A cikin kayan aiki - da - masana'antar mutu, ana amfani da kwatancen gani don bincika daidaiton ƙira da mutuwa.

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Girman Girma | Daga [Min magnification] x zuwa [Max magnification] x, daidaitacce don girman sassa daban-daban da buƙatun dubawa |

| Tsarin Hoto | Hoto mai girman gaske, yana ba da damar gani da kyau na cikakkun bayanai |

| Auna Daidaito | ± 0.005 mm don ma'aunin layi, yana tabbatar da ingantaccen sakamako |

| Tsarin Haske | Fasaloli masu canzawa - ƙarfi da hasken kusurwa da yawa don haɓaka hangen nesa |

Ma'aunin Tsawo na Dijital - Ma'auni Madaidaicin Ma'auni (2.5D Projector)

Ma'aunin tsayi na dijital, galibi ana kiransa 2.5 - Kayan Auna Girma, suna taka muhimmiyar rawa a tsarin binciken mu. Hoton da ke ƙasa yana nuna ma'aunin tsayin dijital da ake amfani da shi, yana auna tsayin kayan aiki tare da daidaito.

Ana amfani da waɗannan ma'auni sosai a cikin saitunan masana'anta don auna tsayi, zurfin, da mataki - tsayin sassa. Suna da mahimmanci musamman wajen samar da madaidaicin kayan aikin injin, kamar waɗanda aka samo a cikin masana'antar kera motoci da na semiconductor.

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Aunawa Range | [Min tsawo] - [Max tsawo] mm, dace da faffadan kewayon sassa tsawo |

| Daidaito | ± 0.01 mm, yana ba da ingantattun ma'auni na tsaye |

| Nau'in Nuni | Nuni na dijital don sauƙin karatu da rikodin bayanai |

| Zaɓuɓɓukan Bincike | Akwai tare da shawarwarin bincike daban-daban don nau'ikan saman daban-daban |

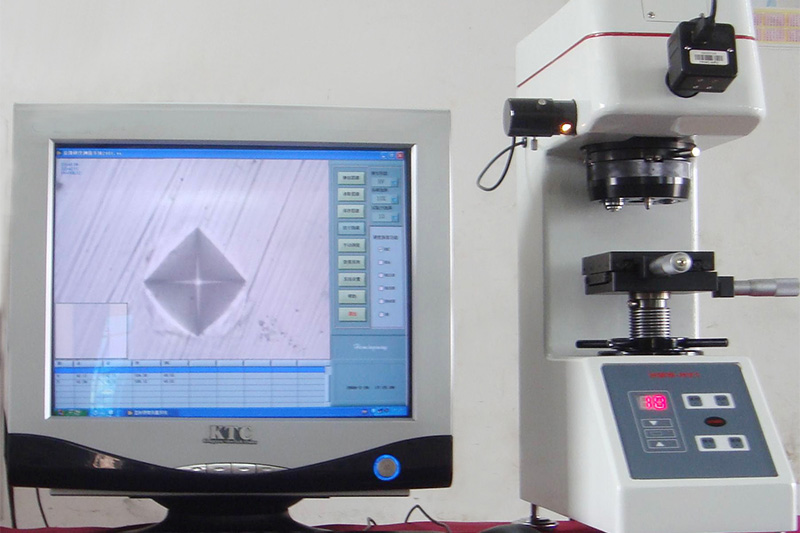

Gwajin Tauri

Gwajin taurin yana da mahimmanci don tabbatar da ingancin kayan da ake amfani da su a cikin ayyukan injin mu. Hoton da ke ƙasa yana nuna ma'aunin taurin da ake amfani da shi don auna taurin samfurin karfe

A cikin masana'antar ƙarfe, gwajin taurin yana taimakawa wajen tabbatar da ingancin kayan da aka gama. Alal misali, a cikin samar da kayan aiki, gwajin gwagwarmaya yana tabbatar da cewa abu zai iya tsayayya da babban nauyi da damuwa yayin aiki. Muna amfani da nau'ikan gwaje-gwaje daban-daban, gami da Rockwell, Brinell, da Vickers, don ɗaukar kayayyaki iri-iri da buƙatun gwaji.

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Rufe Sikelin Hardness | Rockwell: A, B, C ma'auni; Brinell: sikelin HBW; Vickers: sikelin HV |

| Gwajin Ƙarfin Ƙarfi | Ƙarfin gwaji masu daidaitawa don dacewa da matakan taurin abu daban-daban |

| Nau'in masu shiga | An sanye shi tare da indenters masu dacewa don kowane ma'aunin taurin |

| Daidaito | Ma'auni mai girma - daidaito, tsakanin ± [X] raka'a taurin ya danganta da ma'auni |

Surface Roughness Testers

Taushin sararin sama muhimmin abu ne a aikace-aikace da yawa, kuma an ƙera na'urorin gwajin mugun yanayi don auna wannan siga daidai. Hoton yana nuna ma'aunin ma'aunin zafi da ake amfani da shi, yana duba yanayin ɓangaren da aka kera

A cikin masana'antu irin su kera motoci da masana'antu, ƙaƙƙarfan yanayi na iya yin tasiri ga aiki da dorewar abubuwan haɗin gwiwa. Misali, a cikin kayan aikin injin, kammalawar da ta dace na iya rage juzu'i da haɓaka aiki. Masu gwajin yanayin mu na iya auna ma'auni daban-daban, kamar Ra (ma'anar ma'anar lissafi na bayanin martaba da aka tantance) da Rz (matsakaicin tsayi na kololuwa biyar mafi girma da kuma zurfin kwari biyar a cikin tsayin kimantawa).

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Aunawa Range | Ra: [darajar Min Ra] - [darajar Max Ra] µm, wanda ya dace da kewayon ƙarewar saman |

| Nau'in Sensor | Maɗaukakin madaidaicin na'urori masu auna sigina don ingantaccen bayanin martaba |

| Tsawon Samfura | Tsawon samfurin daidaitacce don saduwa da ma'auni na masana'antu daban-daban |

| Data Output | Za a iya fitar da bayanai ta nau'i-nau'i daban-daban don sauƙaƙe haɗin kai tare da tsarin sarrafa inganci |

Microscopes

Microscopes suna da matukar amfani don duba cikakkun bayanai na mintuna akan saman sassa. Hoton da ke ƙasa yana nuna na'ura mai ƙima da ake amfani da ita don bincika wani yanki a babban girma

A cikin masana'antun lantarki da kayan ado, ana amfani da microscopes don duba ingancin kayan haɗin gwiwa, ƙarewar saman ƙarfe masu daraja, da amincin ƙananan abubuwa. Suna baiwa ƙungiyar mu damar gano lahani da lahani waɗanda ba a iya gani da ido.

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Girman Girma | Daga [Min magnification] x zuwa [Max magnification] x, yana ba da damar cikakken bincike a matakai daban-daban |

| Tsarin Haske | An sanye shi da haske mai haske na LED don bayyanannun samfurin |

| Ikon Ɗaukar Hoto | Wasu samfura suna tallafawa ɗaukar hoto don tattara bayanai da bincike |

| Daidaita Mayar da hankali | Daidaitaccen daidaitawar mayar da hankali don ɗaukar hoto mai kaifi a zurfafa daban-daban |

Micrometers

Micrometers daidaitattun kayan aunawa ne waɗanda ake amfani da su don ɗaukar ma'aunin ma'auni daidai gwargwado. Hoton da ke ƙasa yana nuna micrometer da ake amfani da shi don auna diamita na ɓangaren silinda

Ana amfani da su da yawa wajen aikin injina don auna diamita na ramuka, kaurin kayan, da zurfin ramuka. An san micrometers don girman daidaiton su kuma kayan aiki ne mai mahimmanci a kowane madaidaicin yanayin masana'antu

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Aunawa Range | [Min aunawa] - [Max auna] mm, ana samun su a cikin jeri daban-daban don aikace-aikace daban-daban |

| Daidaito | ± 0.001 mm, yana ba da ingantattun ma'auni na layi |

| Anvil da Spindle Design | Madaidaici - maƙarƙashiyar ƙasa da sanduna don daidaiton ma'auni masu aminci |

| Kayan aikin kullewa | An sanye shi da tsarin kulle don riƙe ma'auni a wurin |

Calipers

Calipers kayan aikin auna iri-iri ne waɗanda za a iya amfani da su don auna girman ciki, waje, da zurfin sassa. Hoton da ke ƙasa yana nuna ƙirar dijital da ake amfani da ita don auna faɗin sashi.

Ana amfani da su sosai a masana'antu iri-iri, tun daga aikin katako zuwa ƙirar ƙarfe. Calipers suna ba da hanya mai dacewa kuma daidai don ɗaukar ma'auni mai sauri yayin aikin masana'anta.

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Girman Girma | Daga [Min magnification] x zuwa [Max magnification] x, yana ba da damar cikakken bincike a matakai daban-daban |

| Tsarin Haske | An sanye shi da haske mai haske na LED don bayyanannun samfurin |

| Ikon Ɗaukar Hoto | Wasu samfura suna tallafawa ɗaukar hoto don tattara bayanai da bincike |

| Daidaita Mayar da hankali | Daidaitaccen daidaitawar mayar da hankali don ɗaukar hoto mai kaifi a zurfafa daban-daban |

Toshe Gauges

Ana amfani da ma'aunin toshe don duba diamita na ciki na ramuka da ƙumburi. Hoton da ke ƙasa yana nuna saitin ma'aunin toshe da ake amfani da shi don duba rami a cikin kayan aikin

A cikin kera abubuwan haɗin gwiwa kamar injin silinda, bawuloli, da bututu, ma'aunin toshe suna tabbatar da cewa diamita na ciki sun haɗu da ƙayyadaddun haƙuri. Kayan aiki ne masu sauƙi amma masu inganci don sarrafa inganci a cikin ma'auni masu alaƙa

| Ƙayyadaddun bayanai | Cikakkun bayanai |

| Gauge Diamita Range | [Min diamita] - [Max diamita] mm, ana samun su cikin girma dabam dabam don dacewa da diamita daban-daban |

| Matsayin haƙuri | An kera shi zuwa takamaiman azuzuwan haƙuri, kamar H7, H8, da sauransu, don ingantaccen tabbaci |

| Material | Anyi daga ƙarfe mai ƙarfi mai inganci don karko da juriya |

| Ƙarshen Surface | Ƙarshen ƙasa mai laushi don hana lalacewa ga ɓangaren da ake dubawa |