Cikakken Ƙarfin Sabis

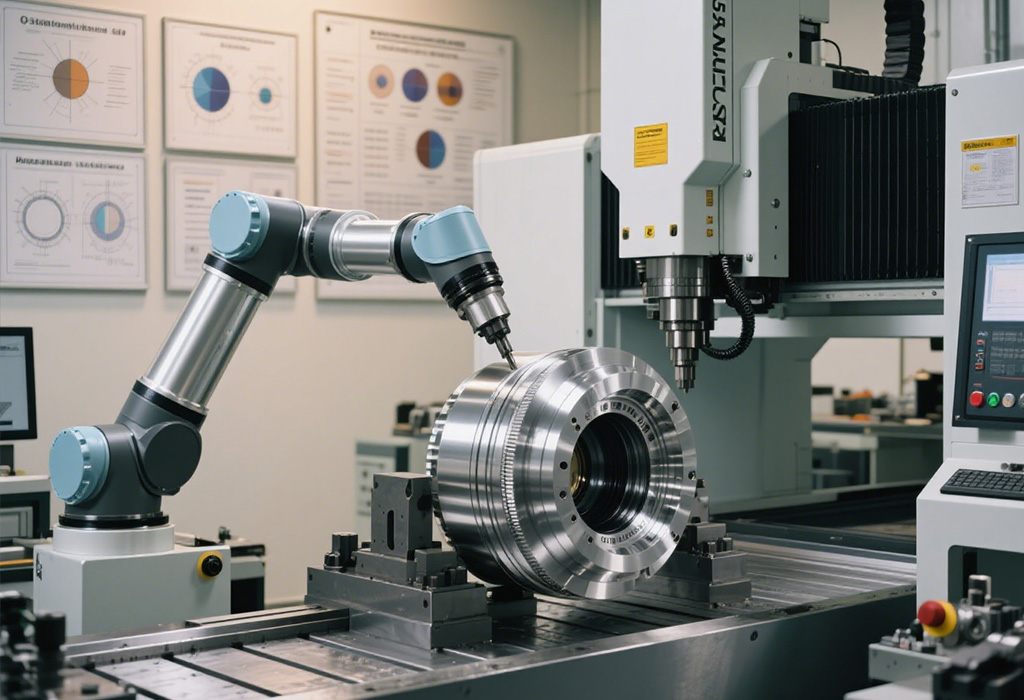

Tebur 1:Kayan Aikin Injin CNC & Ƙididdiga na Fasaha.

| Kashi | Cikakkun bayanai | Maɓalli Maɓalli |

| Nau'in Na'ura | 5-axis CNC machining cibiyoyin (DMG MORI HSC 75 mikakke) | Sama da raka'a 60 na kayan aiki |

| Material Range | Karfe: Aluminum 6061/7075-T6, SS 304/316/17-4PH, Titanium Grade 5, Brass C36000 | Kayayyakin darajar Aerospace (AMS 4928) |

| Rage sarrafawa | Matsakaicin girman niƙa: 1500mm × 1000mm × 800mm | 5-gefe machining a saitin guda |

| Haƙuri daidai | Haƙuri na inji: ± 0.005mm (5-axis) - ± 0.05mm (3-axis) | ISO 2768-mk yarda |

| Bayan-Processing | Anodizing (Nau'in II/III mai wuya), Rufe foda, Nickel chrome plating | ASTM B580 Plating Standards |

Aikace-aikacen Masana'antu & Nazarin Harka

Table 2:Abubuwan da aka Haɓaka & Nasarar Fasaha.

| Masana'antu | Abubuwan gama gari | Babban Halayen Fasaha |

| Jirgin sama | Wuraren injin turbine, madaidaicin kayan saukarwa, gidaje na Avionics | 28% rage nauyi ta hanyar inganta topology FAA DO-160G mai yarda da rawar jiki Ti-6Al-4V da aka yi amfani da shi zuwa ± 0.01mm haƙuri |

| Na'urorin likitanci | Ƙaƙƙarfan aikin tiyata, Ƙaƙwalwar kashin baya, abubuwan da suka dace da MRI | Ti-6Al-4V kofuna na acetabular tare da gama Ra 0.4μm ISO 13485 masana'anta mai tsabta 510 (k) tallafin takaddun shaida |

| Motoci (EV) | Tiren baturi, Hannun dakatarwa, Gidajen motocin lantarki | Aluminum 6061-T6 trays 30% haske fiye da karfe 5-axis machined tashoshi sanyaya 10,000+ samarwa a wata |

| Robotics | Kayan tuƙi masu jituwa, haɗin gwiwar hannu na Robotic, Dutsen Sensor | Gears tare da ± 0.003mm juriya na farar Carbon fiber abun da ake sakawa don rage koma baya 40%. |

| Semiconductor | Masu dako na wafer, Madaidaicin kayan gyara, abubuwan da aka gyara ɗakin ɗakin | 316L bakin karfe da Ra 0.8μm gama ISO class 5 taro mai tsabta Hanyoyin kariya na ESD |

Tsarin samarwa & Tabbatar da inganci

Zane don Haɓaka (DFM)

♦ Binciken samfurin 3D tare da SolidWorks/UG/NX.

♦ Haƙuri tari-up kwaikwayo.

♦ Inganta farashin kayan abu.

CNC Machining & In-Process Inspection

♦ 5-axis machining lokaci guda don hadaddun geometries.

♦ Sake gwada bincike a cikin sake zagayowar.

♦ Real-lokaci SPC saka idanu.

Ikon Ƙarshe na Ƙarshe

♦ Zeiss CMM dubawa (± 0.002mm daidaito)./♦ Majigi na gani don ƙananan siffofi./♦ 100% gwaji na gani & aiki.

Farashin & Lokacin Jagora

| Nau'in oda | Yawan Range | Lokacin Jagora | Factor Factor |

| Samfura | 1-50 raka'a | 3-7 kwanaki | Material & rikitarwa |

| Karancin Ƙara | Raka'a 50-1,000 | 10-15 kwanaki | Ingantaccen tsari |

| Samar da Jama'a | 1,000+ raka'a | 20-45 kwanaki | Kayan aiki amortization |

Takaddun shaida & Biyayya

Tawagar goyon bayan abokin cinikinmu koyaushe a shirye take don taimaka muku a duk tsawon aikin.

ISO 9001: 2015 bokan

AS9100D don abubuwan haɗin sararin samaniya

ITAR rajista

RoHS / REACH mai yarda da yarda

Farashin & Lokacin Jagora

Haɗa ƙirar 3D (MATAKI/IGES) don ƙididdiga na awa 24.